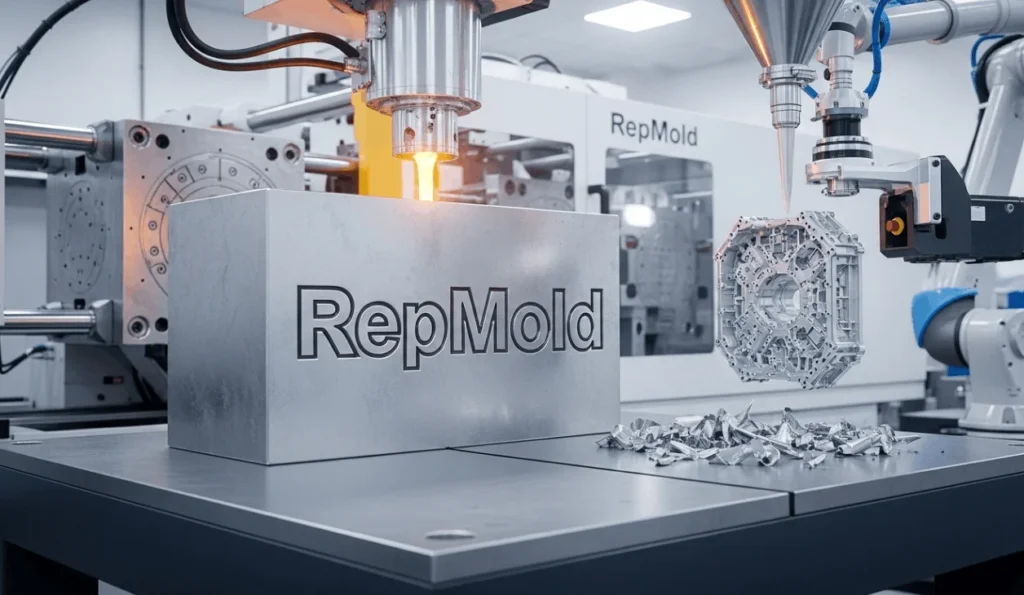

Repmold: Advanced Molding Solutions for Precision Manufacturing

In today’s rapidly evolving manufacturing industry, precision, durability, and efficiency are more critical than ever. One company that has consistently stood out in delivering these qualities is Repmold. Renowned for its cutting-edge molding solutions, RepMold has revolutionized how industries approach production processes, ensuring products meet the highest standards of quality and reliability.

What is RepMold?

Repmold is a leading provider of advanced molding solutions designed to cater to a wide range of industries, from automotive to consumer goods. The company specializes in creating custom molds, offering both prototyping and large-scale production services. Unlike traditional molding techniques, RepMold integrates modern technology with innovative design processes, ensuring that every product is manufactured with precision and minimal material waste.

One of the distinguishing features of RepMold is its focus on customization. Whether a business requires a small batch of prototypes or a full-scale manufacturing run, RepMold provides tailored solutions that align with specific requirements. This adaptability has made it a preferred partner for companies looking to streamline their production processes while maintaining high-quality output.

Key Benefits of Using RepMold

1. Enhanced Precision and Accuracy

Precision is crucial in modern manufacturing, and RepMold excels in delivering molds that meet exact specifications. The company utilizes advanced CAD and CAM technologies to design molds that produce consistent results. This level of accuracy ensures that parts fit perfectly, reducing the need for post-production adjustments and minimizing errors.

2. Cost-Effective Production

One of the most significant advantages of working with RepMold is its ability to optimize production costs. By using efficient molding techniques and minimizing material wastage, RepMold helps businesses reduce expenses without compromising quality. Additionally, the company’s flexible services mean that clients can scale production according to demand, making it an economical choice for both small and large enterprises.

3. Faster Turnaround Times

In industries where time is money, RepMold’s rapid prototyping and production capabilities provide a competitive edge. The company employs streamlined processes that reduce lead times, allowing businesses to bring products to market faster. This agility is particularly beneficial for companies operating in fast-paced sectors, such as automotive and electronics, where speed and efficiency are critical.

4. Sustainable Manufacturing Practices

Sustainability is becoming increasingly important in manufacturing, and RepMold is committed to eco-friendly practices. By implementing techniques that minimize material waste and energy consumption, RepMold ensures that its operations have a reduced environmental impact. Businesses partnering with RepMold not only benefit from high-quality molds but also contribute to greener production practices.

Applications of RepMold

The versatility of Repmold allows it to serve a wide range of industries. Some common applications include:

-

Automotive Industry: RepMold provides high-precision molds for engine components, interior parts, and exterior panels, ensuring vehicles meet stringent quality standards.

-

Consumer Goods: From kitchenware to electronics, RepMold molds enable manufacturers to produce durable and aesthetically appealing products.

-

Medical Devices: The healthcare sector relies on RepMold for creating molds that meet rigorous hygiene and safety standards.

-

Industrial Components: RepMold’s durable molds support the production of heavy-duty components used in machinery and construction.

These applications demonstrate how Custom Mold Manufacturing adapts to varying requirements, providing solutions that enhance efficiency, reduce production errors, and maintain quality across diverse industries.

Why Choose RepMold Over Competitors?

Several factors distinguish RepMold from other molding service providers. Firstly, its commitment to technological innovation ensures clients receive state-of-the-art solutions. Secondly, the company’s expertise in both prototyping and large-scale production means businesses can rely on a single partner for all their molding needs. Lastly, Custom Mold Manufacturing prioritizes client satisfaction by offering personalized support, ensuring that every project is executed flawlessly from start to finish.

Moreover, Custom Mold Manufacturing invests heavily in research and development, constantly exploring new materials, techniques, and technologies. This proactive approach allows the company to stay ahead of industry trends, providing clients with molds that are both innovative and reliable.

Tips for Maximizing Efficiency with RepMold

To get the most out of RepMold’s services, businesses should consider the following tips:

-

Collaborate Early in the Design Process: Engaging RepMold during the design phase helps identify potential challenges and optimize the mold for production.

-

Prioritize Material Selection: Choosing the right material for your product ensures durability, reduces waste, and enhances overall performance.

-

Leverage Prototyping Services: Using RepMold’s prototyping options allows businesses to test designs before committing to full-scale production, saving both time and money.

-

Communicate Clearly: Providing detailed specifications and expectations helps Custom Mold Manufacturing deliver molds that meet exact requirements.

By following these best practices, companies can fully leverage RepMold’s expertise and achieve exceptional results.

Conclusion

In an era where efficiency, quality, and sustainability define success, Custom Mold Manufacturing stands out as a premier choice for advanced molding solutions. Its combination of precision engineering, cost-effectiveness, and eco-friendly practices makes it a trusted partner for businesses across multiple industries. By choosing Custom Mold Manufacturing, companies not only improve their manufacturing processes but also gain a competitive advantage in the market.

Whether you are producing automotive components, consumer products, or medical devices, Custom Mold Manufacturing delivers the reliability, speed, and innovation needed to excel. Investing in RepMold solutions means investing in the future of high-quality manufacturing.